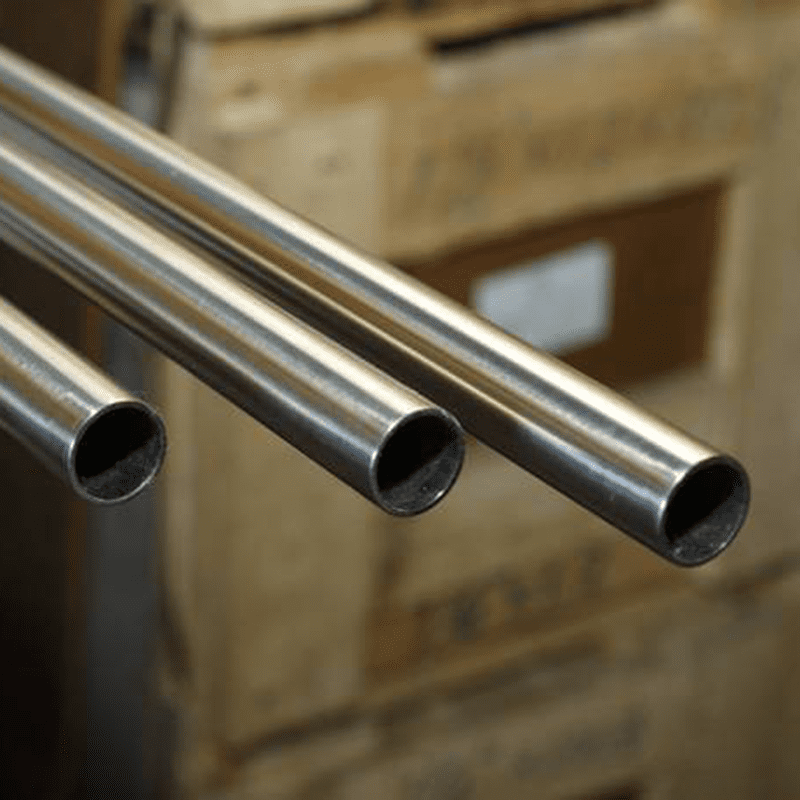

In the complex world of construction and manufacturing, stainless steel seamless pipes represent a pinnacle of engineering achievement. Crafted through sophisticated processes to ensure uniformity and strength, these pipes offer a seamless construction that stands up to high pressures and corrosive environments with unparalleled grace. Their robustness, combined with a resistance to corrosion, makes them indispensable in industries ranging from oil and gas to pharmaceuticals. This guide explores the manufacturing process, benefits, and applications of stainless steel seamless pipes, providing insights into their essential role in today's industrial landscape.

The journey of stainless steel seamless pipes begins with solid steel billets, heated and then stretched over a form until they take the shape of hollow tubes. This process, known as extrusion, involves several steps that refine the metal's structure and enhance its properties. The absence of welds in seamless pipes provides them with superior strength and flexibility, making them suitable for high-pressure applications. Advanced technologies in manufacturing ensure that these pipes meet the rigorous standards required for their use in critical environments.

Stainless steel seamless pipes boast a myriad of advantages over their welded counterparts and other materials. Their seamless construction provides enhanced strength and durability, making them ideal for high-pressure applications. The corrosion resistance of stainless steel ensures longevity and reliability in harsh environments, reducing the need for frequent replacements and maintenance. Furthermore, the versatility of these pipes allows for their use across a wide range of industries, from chemical processing to water treatment systems.

The applications of stainless steel seamless pipes are as diverse as they are crucial. In the oil and gas industry, they are used for the safe transportation of products under high pressure. Chemical processing plants rely on these pipes for the transport of corrosive substances. Additionally, their use in water treatment facilities highlights their importance in providing clean and safe water. The adaptability of stainless steel seamless pipes to different environments makes them a key component in numerous industrial applications.

When comparing stainless steel seamless pipes with welded pipes, several factors come into play. Seamless pipes offer greater strength and reliability due to their uniform structure, making them suitable for high-pressure applications. While welded pipes may be more cost-effective for certain uses, the seamless variety provides a higher level of integrity and resistance to corrosion, making them a preferred choice for critical applications where failure is not an option.

The future of stainless steel pipe manufacturing is poised for innovation, with sustainability and efficiency at the forefront. Advances in manufacturing technology promise to reduce environmental impact while maintaining the high quality of these essential components. The industry is moving towards greener practices, including the use of recycled materials and energy-efficient processes, ensuring that stainless steel seamless pipes remain a staple in industrial applications while aligning with global sustainability goals.

Q: What is the lifespan of stainless steel seamless pipes? A: The lifespan of stainless steel seamless pipes can vary greatly depending on their environment and use but typically ranges from 20 to 40 years. Factors such as exposure to corrosive substances and physical stresses can affect their durability, but with proper installation and maintenance, they often exceed their expected lifespan.

Q: Can stainless steel seamless pipes be used for drinking water systems? A: Yes, stainless steel seamless pipes are an excellent choice for drinking water systems. Their corrosion resistance ensures that the water remains free from contamination, while their strength and durability support the infrastructure of water supply systems.

Q: How do stainless steel seamless pipes withstand extreme temperatures? A: Stainless steel seamless pipes are designed to withstand extreme temperatures due to their unique composition and manufacturing process. The alloying elements in stainless steel, such as chromium and nickel, provide high-temperature strength and improve resistance to oxidation and corrosion at elevated temperatures.